GAM (Gas Assisted Molding) EQUIPMENTS

- Everything you need for GAM technology can be provided here

Gas-Assisted Injection Control System

Model Reference: EJS SF-1 / 2

It cooperates with injection molding machines (of any brand or company) to control the pressure level and time of high-pressure nitrogen injection. Our EJS series controller provides 1 to 4 gas injection gas channels and 2 signal interfaces that can be provided to one or two injection molding machines at the same time.

● Programmable PLC and 7-inch color touch screen, user-friendly and easy-to-use control interface.

● Advanced design, precise structure, high response sensitivity, strong reliability, and stable repeated output air pressure.

● Easy and flexible installation and connection to different injection machines.

● Most economic and affordable system at small investment budget.

It c

2-in-1 Integrated Gas-Assisted Injection System

Model Reference: PDS60-YT-1 / 2

This integrated machine is a simple, low-cost gas-assisted molding system ideally for small and medium-sized plastic processing enterprises.

● Boost low-pressure nitrogen (greater than 10 bar) to a maximum pressure of 350 bar.

● Supercharger-ADI (Pneumatic Pump) that only needs nitrogen gas source no less than 10 bar, and it is safe, reliable and stable.

● has the characteristics of advanced design, precise structure, high response sensitivity, strong reliability, and stable repeated output air pressure.

● Programmable PLC and 7-inch color touch screen, user-friendly and easy-to-use control interface.

● Simpler and easier to install and debug, high production flexibility, and low maintenance costs.

● Automatic safety alarm.

Nitrogen Generator

Model Reference: SPN series

● Easy installation: compact structure and is skid-mounted as a whole.

● Affordable: simple nitrogen production method, by air only and low electrical energy consumed. Low operating cost, low energy consumption but high efficiency.

● Automation: PLC controlled full-automatic operation, nitrogen flow pressure and pressure purity adjustable display.

● High-quality components for stable and reliable operation by more than one million times, low failure rate low maintenance cost.

● Stable nitrogen purity:

automatic alarm system for exceeding the limit.

● High-quality carbon molecular sieve: normal service life can reach 8 to 10 years and more.

● Automatic evacuation system for unqualified-nitrogen.

● Ideal purity selection range: can be adjusted arbitrarily between 98% -99.9%. Optional with a nitrogen purifier that can produce 99.9995% high-purity nitrogen.

High-Pressure Nitrogen Booster

Model Reference: DL series

● With compressor capable of boosting to 350bar.

● Good for various plastic products that have different injection pressure requirements,

● High quality, reliability and long service years for minimum 10 years.

● Suitable and good for strict production environmental requirements.

● Different types of high-pressure nitrogen boosters can be provided according to customer requirements.

High-Pressure Nitrogen Booster

Model Reference: XL series

● With compressor capable of boosting to 350bar.

● Good for various plastic products that have different injection pressure requirements,

● High quality, reliability and long service years for minimum 10 years.

● Suitable and good for strict production environmental requirements.

● Different types of high-pressure nitrogen boosters can be provided according to customer requirements.

High-Pressure Nitrogen Booster

Model Reference: EJS-350 series

It uses full oil-free reciprocating piston high-pressure nitrogen compressor.

● All-oil-free lubrication structure, no need to add lubricating oil that can reduce overal operation cost and failure rates.

● Automatic fault alarm and reminder functions.

● Double-row vertical structure with low vibration, low noise and small lateral load.

● Four-stage supercharging water cooling system to effectively reduce the heat.

● Excellent performance, stable operation, high efficiency and energy saving, long service life, simple operation, and low use and maintenance costs.

OTHER EQUIPMENTS

- Everything you need for GAM can be provided here

High-gloss traceless injection molding System

Model Reference: JXT series

Introducing the latest technology from Italy: High gloss steam injection molding equipment.

● PLC processor + human-machine interface, high control precision, easy operation and monitoring, optional with touch-type.

● Full closed-loop system controls the detection of the input and output temperature.

● It can achieve segmented heating and rapid cooling, single and double-way mold temperature detection (optional), input and output pipes using stainless steel pipes, and multiple sets of input and output interfaces.

● Equipped with: extremely fast heating 180C, extremely fast cooling below 30C, cold and heat conversion control function, with high recovery rate at 95%.

● Automatic cleaning function.

Heating energy saving system

"Quartz superconducting energy-saving heating technology" is different from previous purely conductive and pure infrared radiation heaters. The gas auxiliary equipment adopts a special structural design, which provides a conduction path for the transfer of thermal energy and adds a reflection device for infrared radiation.

● Energy saving effect by 20% -70%.

● Fast thermal response, the same power, effective power density increased by 30%.

● Precise temperature control, no overshoot, temperature control accuracy reaches ± 1 ℃.

● No over-temperature, low surface temperature of heating element, small temperature gradient, light and thin heat insulation.

● Reduced surface temperature is to avoid burns, improve workshop environment for radiation.

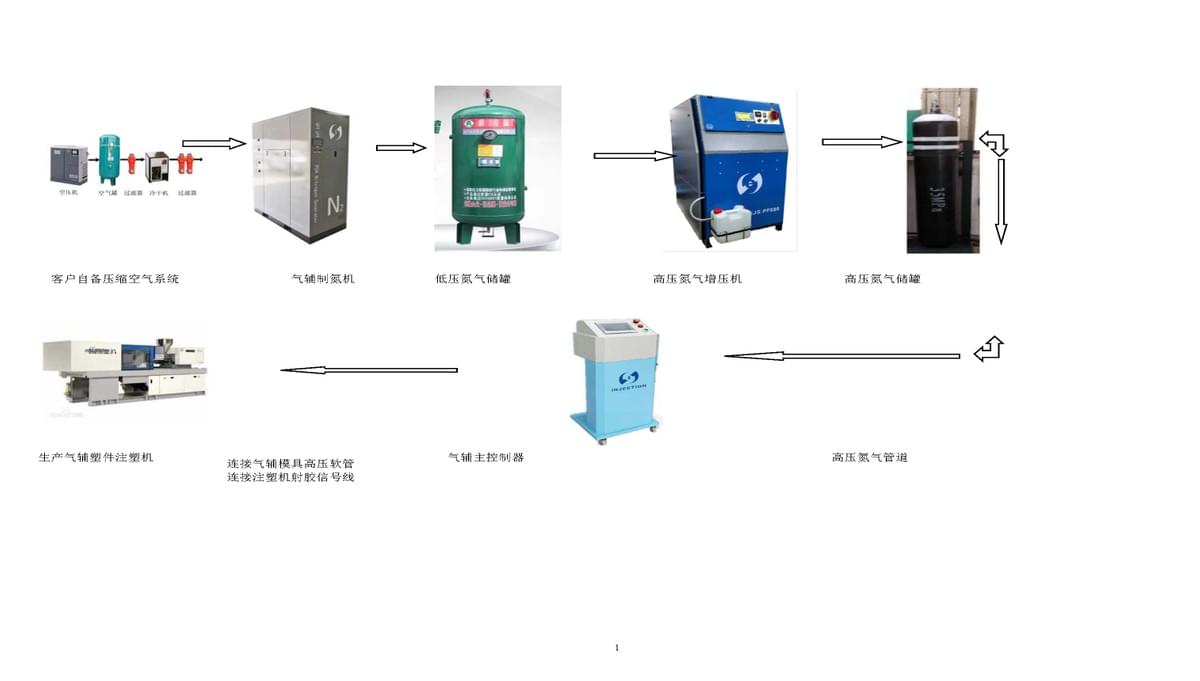

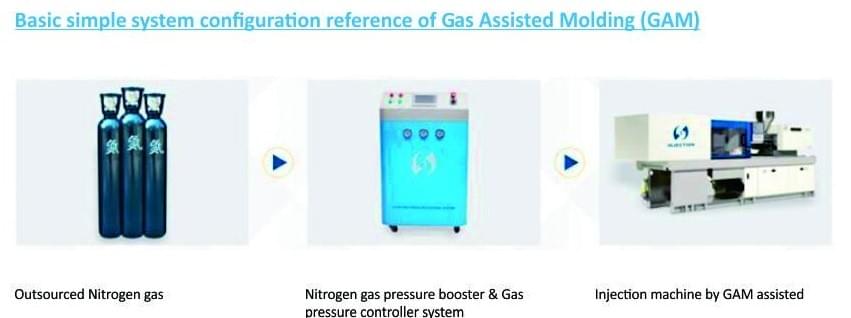

Introduction of Gas Assisted Injection Molding technology

GAM (Gas Assisted Molding) system

REF PRODUCTS PRODUCED BY GAM

- Everything you need for GAM can be provided here

Coat hanger

Good for mass production for all kinds of plastic coat hangers (ABS, PP, Fully degradable biological material etc.) with less material and lower cost by up to 40%.

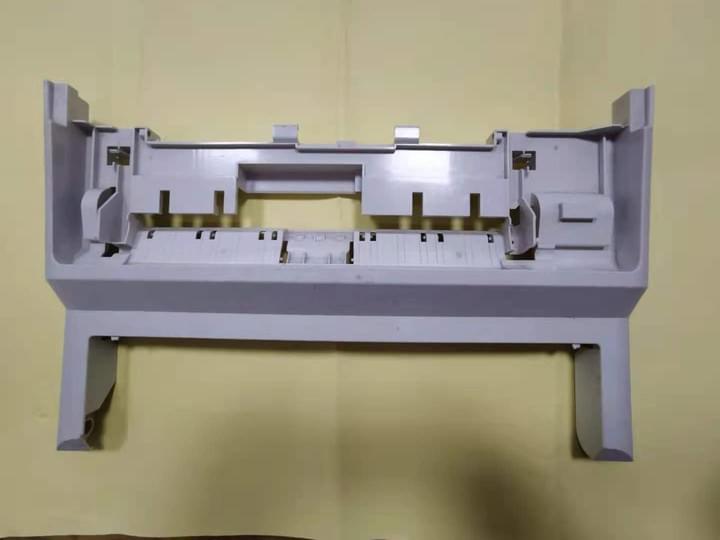

Plastic parts

Good to produce different kinds of plastic parts by highly complicated designs, can help to reduce visible weld lines on surface and internal stress inside plastic parts.

Plastic parts

Good to produce different kinds of plastic parts by highly complicated designs, can help to reduce visible weld lines on surface and internal stress inside plastic parts.

Many others

Good to produce many other kinds of products like electronic parts (mouse, keyboard... ), Auto car parts, Chairs, etc.

About Enjiesen

Shenzhen Enjiesen Technology Co., Ltd is a company specializing in R&D, Manufacturing and Service in Gas Assisted Molding (GAM) equipment and Rapid Heat & Cool Mold Temperature Controller technology (Plastic parts in High gloss, No visible weld line) for more than 12 years.

In China, our company has been certified and working as qualified supplier of the GAM equipments for big companies like BYD (Auto parts), Foxconn, etc since the year of 2015.

We also supply GAM equipments to the other countries around the world, like Vietnam, Thailand, Mexico, Poland etc, as we have complete know-how, technology, service capability and adequate experience to be a long term partner with our clients all over the world.

Our vision is “Quality from Speciality, Innovation for Future, Service is Value”, we sincerely work hard to create the highest value for our clients, by providing the most high quality product and service.

Contact

If you have any related questions, please send us a message.

No. 14, Lian Feng Road, Xinsheng District, Long Gang, Shenzhen, Guangdong, China0086-755-89909287No. 14, Lian Feng Road, Xinsheng District, Long Gang, Shenzhen, Guangdong, China0086-755-89909287

Copyright © 2019 - Proudly built with Strikingly